Published: 4 August 2014

Category: News

In recent years, metal theft has grown increasingly common. Rising prices mean that metal has become an attractive target for organised criminals and opportunistic thieves. Copper is particularly appealing thanks to its high price and common use in infrastructure across the UK.

The rail industry has been particularly badly affected by copper theft, as the metal is commonly found in vital power, signalling and control cables across the network. Disruption caused by copper theft is estimated to have cost £770 million in the UK in 2012 alone. What’s more, according to a recent report, French railway operators experienced around 5,800 hours of delays in just one year as a result of copper theft.

As one of the world’s leading cable producers, Nexans has been actively involved in efforts to find a solution a problem which damages infrastructure, costs millions of pounds and inconveniences the people using the rail network.

One of the critical challenges is making cables less attractive to thieves. One approach is to reduce the amount of copper and incorporate less valuable metals like aluminium in the cable. However, this solution would require larger cross-sections due to aluminium’s lower conductivity. In turn this causes problems for installers and maintenance crews who have to deal with two different standards. Aluminium also tends to buckle over time when exposed to shocks, vibrations and stress at the trackside.

In response to this, Nexans recently developed its RHEYRAIL® solution for surface-installed grounding wires, which are situated between pole and rails. A combination of copper and galvanised steel wires in the centre and outer layer mean that severing the cable is extremely difficult, while the cable’s value is much lower on the black market compared to pure copper.

RHEYRAIL® is currently being installed across the German rail network, with future installation across South America and Scandinavia also mooted.

Making cable more identifiable discourages scrap yards from buying it and helps police trace the cable, after it has been stolen. The traditional approach to marking the origin and ownership of railway cable has been to print identity markings on the rubber insulation. However, thieves are easily able to get around this by burning away the rubber. Most thieves would do this anyway, as offering pure cable makes offloading the cable easier.

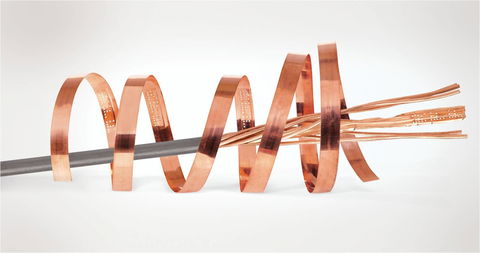

Nexans’ own solution to this problem has been to develop its CORE-TAG® product. In contrast to more expensive tagging techniques – such as using rare earth metals to tag cables - CORE-TAG® involves installing a coded, fire-resistant copper tape that is intertwined in the conductor.

Every 30 centimetres a dot-matrix series of perforations spells out an identification code or name, which can be read by the naked eye. The markings make it easy to identify the stolen copper, even after the insulation has been burnt off. Since the tape is embedded along the length of the conductor, it is virtually impossible for the thief to remove it. The fully patented cable is currently available for grounding cables and be easily adapted to any conductor with a cross-section greater than 16 mm2. What’s more, CORE-TAG® cables are just as easy to handle and install as conventional cables and do not require special tools or accessories.

Cable theft continues to blight the UK, with the rail industry suffering worst of all. Traditional approaches to cable theft such as substituting aluminium for copper and marking rubber insulation have largely proved ineffective. New technologies like those developed by Nexans offer rail operators and others stakeholders in the supply chain the opportunity to stem the tide of cable theft and mitigate its devastating effects.